Universities & education leadership and expertise

Thanks to our vast expertise and fully equipped laboratories, we can help you capitalise on new opportunities, or investigate and resolve glass-related issues. We’ve worked on many successful national and international projects, both commercial and grant funded.

Universities & education services

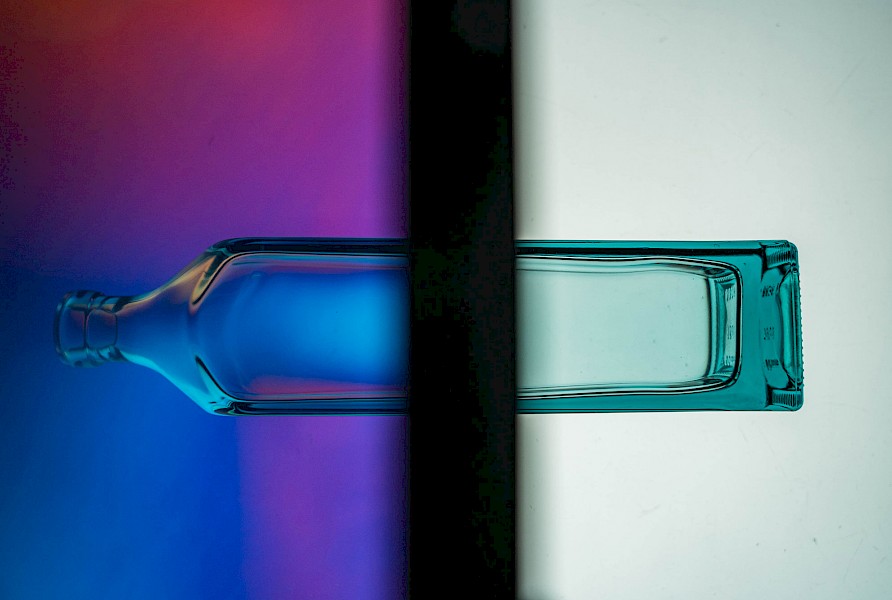

Bespoke glass development and manufacture

We can create glass materials with properties designed to meet the specific requirements of your research group. Previous examples include

- oil and gas and carbon capture – developing controlled dissolution glasses to increase rock formation integrity, and developing the manufacturing process for trials in the field

- nuclear – developing viable glasses for use in nuclear waste thermal treatment

- mainstream manufacture – developing glass compositions that utilise waste ashes

- photonics – producing laser gain materials for q-switch and ultra-fast lasers at a range of wavelengths, for example, tuneable 1050 nm and 1530 nm

- biomedical – producing recognised and published bioactive glasses and unique compositions, for example, 45S5

Products this service is relevant to:

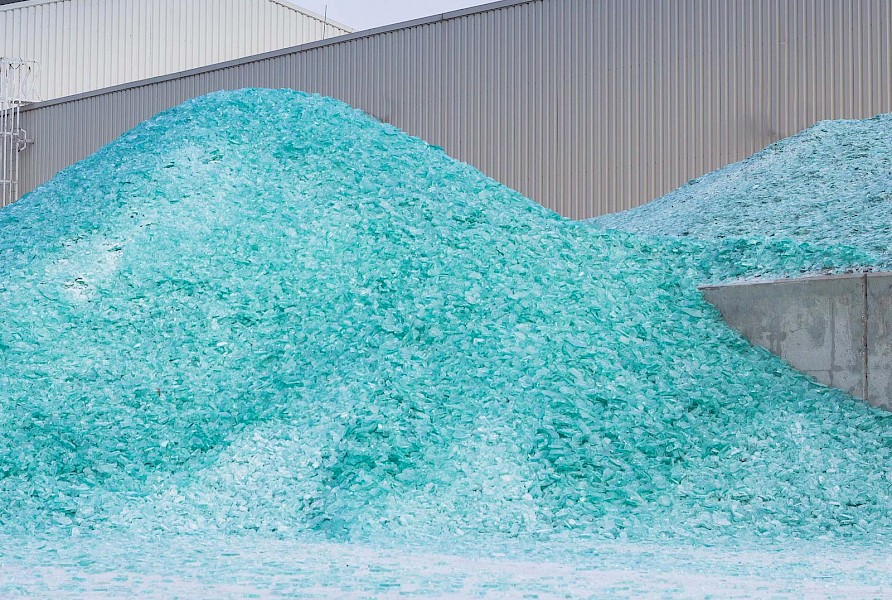

Recycled content and sustainability

We support work in recycling, sustainability and the circular economy by offering a unique perspective of glass as a material. We can audit new and existing processes, review material availability and demand, and evaluate processes and energy efficiency

Products this service is relevant to:

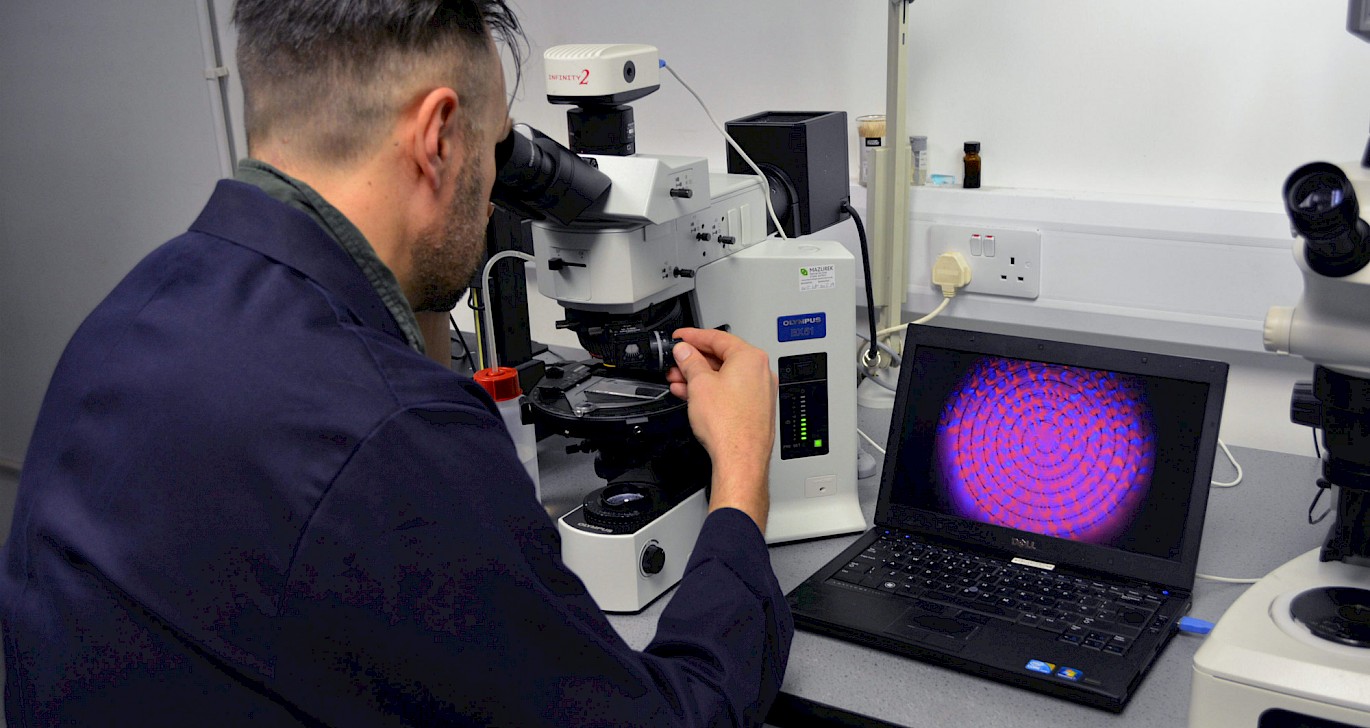

Materials characterisation

Using our in-house characterisation tools, we can determine a wide range of properties relevant to your materials. This ensures product specifications are met and they are fit for purpose.

Products this service is relevant to:

Finite element analysis (FEA) modelling

Through FEA modelling, we can simulate critical processes across a range of scales to provide detailed information about heat transfer, thermal distribution, thermo-mechanical effects and mechanical stresses. This provides important insights related to design and new process development.

Emissions monitoring and modelling

Our MCERTS-accredited emissions monitoring team uses a mobile laboratory to monitor trials.

Using modelling, we simulate the environmental impact of glass manufacturing processes and products. This provides vital insights related to process development, for example, fuel switching and raw material substitution.

Client testimonials

Additional services

R&D and innovation

We have unrivalled glass expertise across a broad range of sectors and can help you develop and optimise your scientific glass applications.

Training and webinars

Our in-house and external training courses teach organisations about various areas of glass production, such as packaging, analysis, and performance.

Consultancy

Our technical experts can provide you with market advantage, knowledge and technical input to processes or products, or develop entirely new and innovative glass formulations, uses or treatments.