Photonics leadership and expertise

Our experts formulate, design and produce bespoke glass photonic materials specifically aligned to your needs. Together, we can develop commercially viable technologies that are guaranteed to meet precise quality and performance requirements.

Photonics services

Bespoke glass development and manufacture

We can design and fabricate bespoke materials that meet your specific requirements, enabling you to expand your optic and photonic applications.

As the sole manufacturer of photonic glass in the UK, we have the expertise to develop and produce laser gain material for q-switched and ultra-fast lasers at a range of wavelengths, for example tuneable 1050 nm and 1530nm.

Our facilities have the capacity to produce large volumes of materials suitable for applications in scientific research, communications, defence and biomedical diagnostics.

Products this service is relevant to:

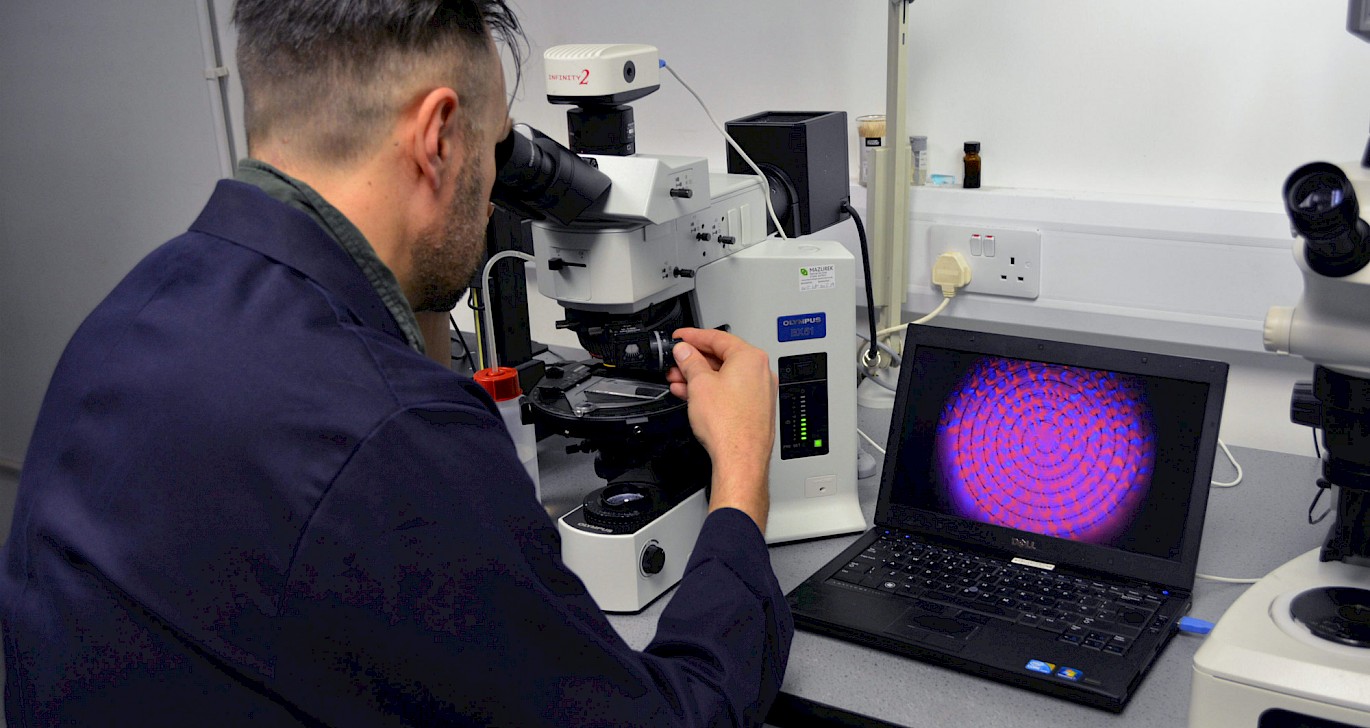

Fitness for purpose testing

Using our photonics, optics and glass materials expertise, we can identify faults and failures in components, glass and crystalline materials.

We use SEM, EDX and FT-IR analysis alongside other techniques to detect defects such as misapplied organics, coating defects and refractive index variances.

This analysis helps prevent customer complaints and reduces wastage. It also enables your supply to continue, minimising costly pauses in production.

Products this service is relevant to:

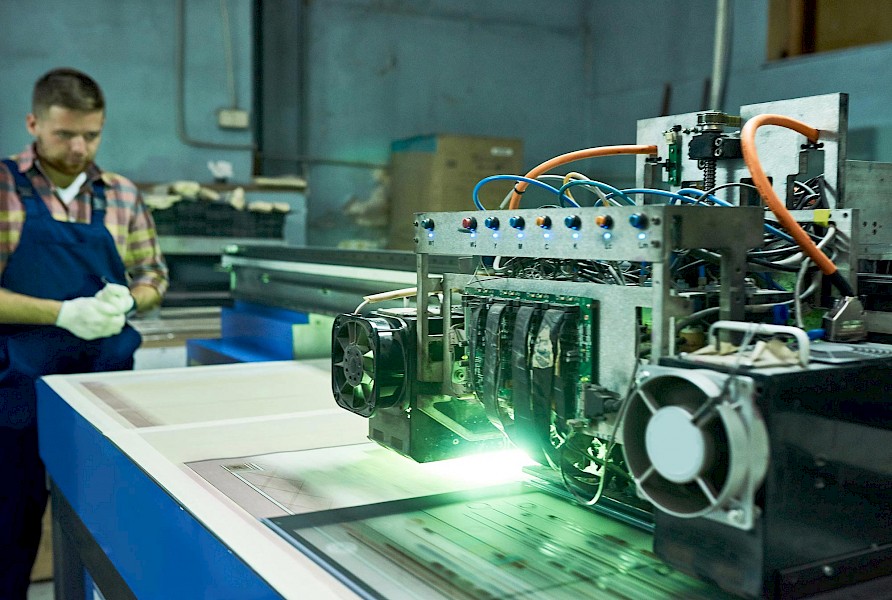

Laser process development

We can help you develop laser processing techniques tailored specifically to glass materials.

We have specialist expertise in areas including laser welding technologies (glass to glass/glass to other materials), laser cutting, additive manufacture (3D printing) and targeted property modification.

Working together, we can develop new products for sectors such as micro-machining, biomedical technologies and advanced optics.

Products this service is relevant to:

Finite element analysis (FEA) modelling of laser processes

We provide finite element analysis (FEA) modelling to investigate heat transfer and stress generation during laser processing and use. This ensures the reliability of your processes and prevents product failure.

Material property characterisation

Using characterisation tools, our experts can determine a wide range of properties relevant to optical and photonic materials. This ensures product specifications are met and they are fit for purpose.

Client testimonials

Additional services

R&D and innovation

We have unrivalled glass expertise across a broad range of sectors and can help you develop and optimise your scientific glass applications.

Training and webinars

Our in-house and external training courses teach organisations about various areas of glass production, such as packaging, analysis, and performance.

Consultancy

Our technical experts can provide you with market advantage, knowledge and technical input to processes or products, or develop entirely new and innovative glass formulations, uses or treatments.