Biomedical & pharmaceutical leadership and expertise

We have over 40 years’ combined experience in performing chemical and pharmaceutical testing for world-leading brands in the glass and pharmaceutical industries. Our experts have published scientific papers in this area and are members of the TC2 and TC12 technical committees.

Biomedical & pharmaceutical glass services

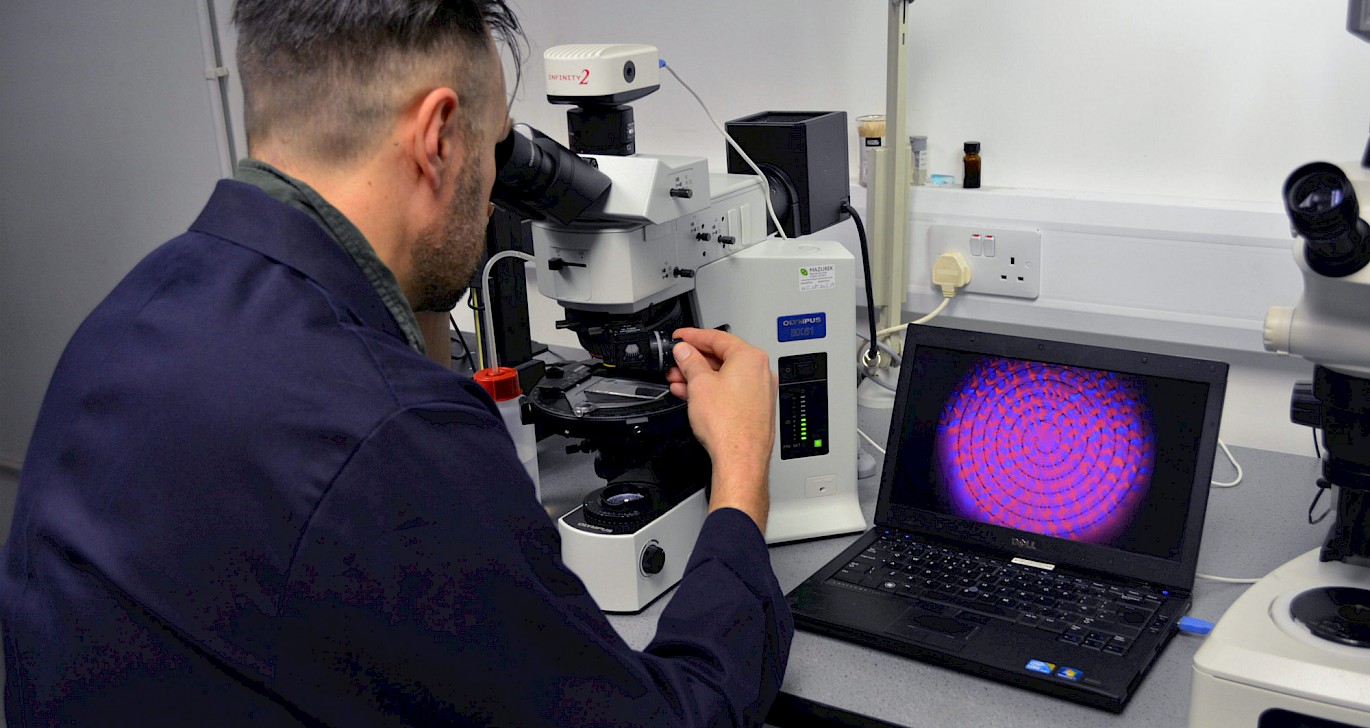

Glass failure analysis

Pharmaceutical companies are ultimately responsible for ensuring the stability of the containers their products are stored in. Using glass failure (or fracture) analysis, we can offer assurances by completing preventative quality assessments and performance testing to ensure due diligence.

Our glass failure analysis also enables us to determine the root cause of a glass breakage in the event of product failure. This comprehensive service combines glass fractography, laboratory analysis and microscopy, on-site investigation, auditing, inspection and expert witness support (if required by a failure scenario).

As well as specialist expertise, we can guarantee independence, confidentiality, speed and flexibility.

Products this service is relevant to:

Glass delamination studies

Glass delamination in pharmaceutical vials and glass packaging occurs when visible flakes or glass lamellae appear. We offer both investigative analysis where delamination is suspected, and propensity studies for assessing delamination risk. This includes the suggested approach detailed in the United States Pharmacopoeia (USP) 1660 and referred to in the European Pharmacopoeia.

We work with pharmaceutical companies to ensure a glass container’s suitability for the pH of the product, the processing involved (including sterilisation and autoclaving) and the handling and storage conditions for the filled product. We also carry out studies at pre-determined temperatures, relative humidity levels, and over time periods that simulate the actual or accelerated ageing of filled products. This can predict the delamination propensity, determining the suitability or compatibility of different drug formulations.

We also offer two standard delamination study packages with the option to be able to tailor this to your specific requirements.

Products this service is relevant to:

Conformity to dimensional specifications

We help glass manufacturers measure and verify the critical dimensions of a product against specific requirements. Our intricate measuring processes can prevent issues related to packaging and decorating glass containers, such as the application of lids and labels.

The areas we measure include thread dimensions, internal bores, verticality or ovality, depending on the product and your needs.

Products this service is relevant to:

Pharmaceutical testing and verification

We are leading experts in pharmaceutical glass verification. We provide pharmaceutical testing and a range of analytical, glass quality assessment, mechanical testing and specialist services for glass used throughout the industry.

We regularly batch test pharmaceutical glassware for a range of global pharmaceutical manufacturers, importers and suppliers, verifying pharmaceutical compliance, dimensional specifications and mechanical performance properties.

Products this service is relevant to:

Extractable elements analysis (according to ICHQ3D)

This service is used to determine the amount of elemental impurities and migration in drugs products. The test method involves an accelerated test procedure to encourage leaching of specified elements from the glass inner surface. These elements are defined by the ICH Q3D as elements to be quantified with defined limits within the document itself.

Pharmaceutical manufacturing line auditing

In order to identify the point in the supply chain that could be responsible for a product issue identified by our product testing and analytical team, a line audit of the pharmaceutical production process from receipt of raw materials to dispatch can provide further supporting information to determine a possible point and how this can be overcome to eliminate the product issue. We have experience in many different glass production processes and will also be able to advise on possible production process improvements to maximise productivity.

Bespoke glass development and manufacture

Our experts provide a series of small-scale melting trials to confirm the suitability of new raw materials in glass production. We use comparative melting trials to establish differences between compositions or refining systems. The normal trial we offer is based on melting four glasses. The melts are all made to produce 250g of glass. We study the melting and refining of each formulation for 30, 60, 90 and 120 minutes, at a temperature comparable with the customer’s melting temperature.

The trials can also improve melting and refining performance and identify possible contamination. Plus, from an environmental perspective, it enables us to recycle more waste products.

Bespoke dissolution glass development and testing

The dissolution behaviour is an important characteristic of glasses used in biomedical applications. We can help you develop an understanding of the dissolution behaviour of your particular glass composition by relating dissolution processes to the glass morphology and chemistry combined with practical dissolution testing.

Glass composition analysis

We can verify and benchmark compositional variations in your pharmaceutical containers. Our experts can analyse standard and exotic glass compositions, including commercial (soda-lime-silicate glass) and borosilicate glass. And they can diagnose production, batch and contamination issues.

We use ISO/IEC 17025 accredited composition analysis to identify glass, raw materials, refractories, dusts and other inorganic materials. The analysis is typically carried out by x-ray fluorescent spectrometry (XRF). But for exotic/specialist glasses, specific requirements or trace element analyses, additional methods can be used. They include wet chemistry, atomic absorption spectroscopy (AA) and inductively coupled plasma optical emission spectrometry (ICP-OES).

Client testimonials

Additional services

R&D and innovation

We have unrivalled glass expertise across a broad range of sectors and can help you develop and optimise your scientific glass applications.

Training & webinars

Our in-house and external training courses teach organisations about various areas of glass production, such as packaging, analysis, and performance.

Consultancy

Our technical experts can provide you with market advantage, knowledge and technical input to processes or products, or develop entirely new and innovative glass formulations, uses or treatments.