Glass manufacturing leadership and expertise

Our global reputation for supporting the glass manufacturing sector is thanks to our world-leading expertise. Many of our specialists have a manufacturing background, with extensive knowledge of its processes and requirements. They provide analysis, testing, verification, troubleshooting and technical support to glass manufacturers worldwide.

Glass manufacturing services

Glass failure analysis

Circumstances surrounding broken glass during the glass production process can often be unclear. Product failure can result in disputes between glass manufacturers and suppliers, or with the end user. Glass failure (or fracture) analysis is a powerful tool enabling us to determine the root cause of a glass breakage. We can also perform preventative quality assessments and performance testing to ensure due diligence is completed before products are placed on the market.

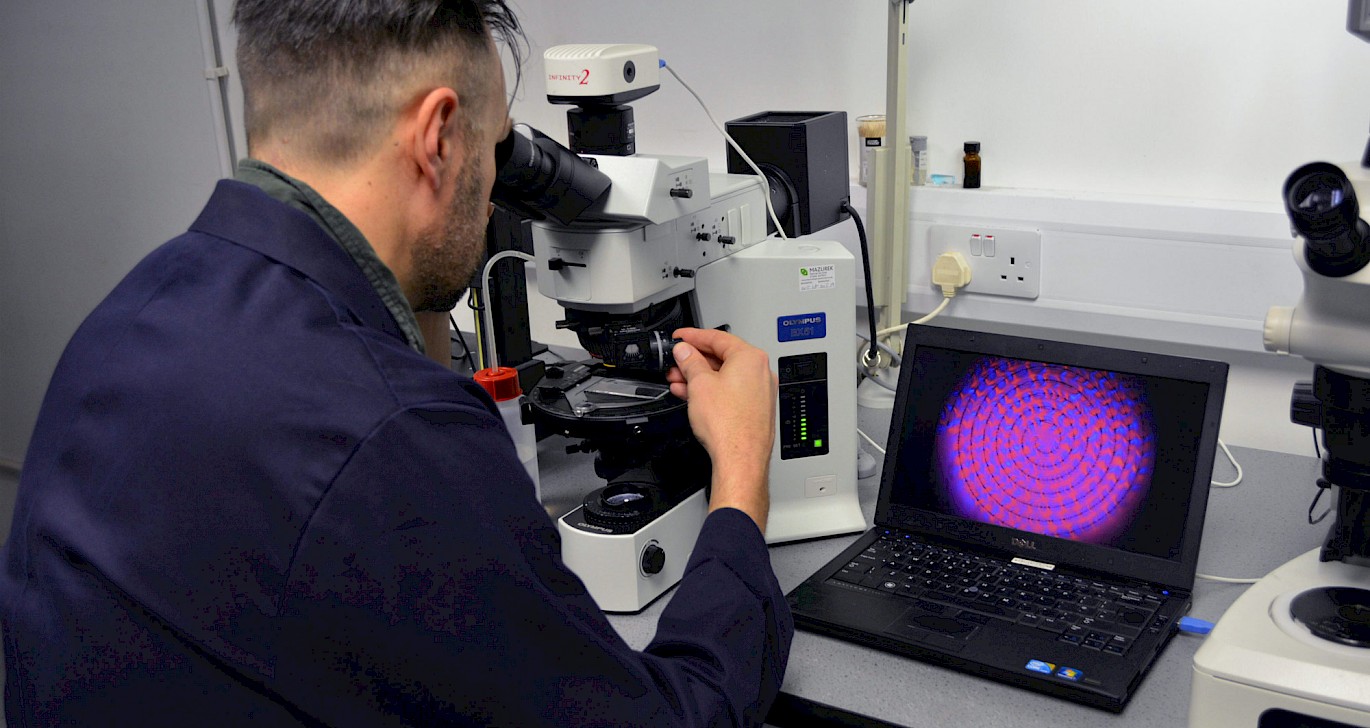

Using broken glass fragments and intact samples, we can diagnose the true cause of glass failure. Our comprehensive glass failure analysis service combines glass fractography, laboratory analysis and microscopy on-site investigation, auditing, inspection and expert witness support (if required by a failure scenario).

As well as specialist expertise, we can guarantee independence, confidentiality, speed and flexibility.

Products this service is relevant to:

Glass composition analysis

If you need to verify and benchmark compositional variations in your glass, we can help. Our experts can analyse a range of glass types, including standard and exotic glass compositions, including commercial (soda-lime-silicate) and borosilicate glass. And they can diagnose production, batch and contamination issues.

We use ISO/IEC 17025 accredited composition analysis to identify glass, raw materials, refractories, dusts and other inorganic materials. The analysis is typically carried out by x-ray fluorescent spectrometry (XRF). But for exotic/specialist glasses, specific requirements or trace element analyses, additional methods can be used. They include wet chemistry, atomic absorption spectroscopy (AA) and inductively coupled plasma optical emission spectrometry (ICP-OES).

In addition to our expertise, we offer a rapid turnaround, plus independent, accredited and reliable results.

Products this service is relevant to:

Glass defects and contamination analysis

Our experts can identify and analyse defects resulting from glass manufacturing so you can prevent them from occurring in the future. We conduct composition analysis of inclusions, stone, cord, knot, bubbles and blisters to surface contamination, plus delamination, misting and bloom. We can also assess defects and quality concerns in finished products.

Plus, in addition to reporting on composition and causes of defects, we can provide expert technical support to identify solutions and quickly resolve production issues.

We can provide our laboratory analysis on a fast and urgent turnaround for rapid diagnostics and fault resolution.

Products this service is relevant to:

Glass quality assessment

We provide reassurance to clients through the provision of due diligence testing and technical support – ensuring the quality and performance of your glass products. Our experts can help you meet container-specific industry standards and all aspects of quality, performance and fitness-for-purpose requirements for carbonated (TEC 7) and non-carbonated (TEC 9) glass packaging.

We offer a comprehensive range of analysis, testing, assessment, and consultancy support to determine the quality of your glass. The packaging we work with includes bottles, jars, flaconnage, vials and other moulded container glasses.

Glass durability and elemental analysis

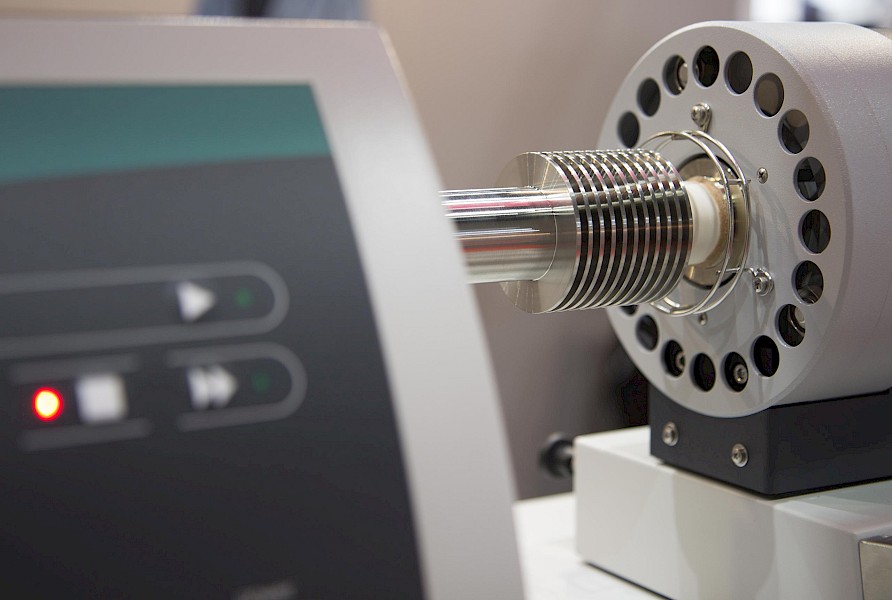

We offer testing to ensure your glass has the appropriate level of chemical resistance and meets all the criteria required to comply with international and industry standards. Our durability analysis determines the environmental and chemical resistance of a product through exposure to a range of acids, bases, water, or other stimulants. Following specific standards/test methods or entirely bespoke protocols we can quantify the levels of particular elements to give you confidence in your product.

This is particularly important for chemically sensitive products, such as parenteral pharmaceuticals. However, it is also important to ensure the safety of both packaging and preparatory surfaces and vessels for foods and drinks. And for compliance/due diligence/personal confidence.

Testing is available for all types of glass composition and products, including the most common soda-lime-silicate (SLS) and borosilicate glasses.

Conformity to dimensional specifications

Our intricate measuring processes can prevent glass manufacturers from experiencing issues within the complexities of packaging when it comes to the next stage of the process, such as labelling.

We can measure and verify the critical dimensions of your product against specific client requirements. These may include thread dimensions, internal bores, verticality or ovality, depending on the product and customer needs.

The specialist equipment we use for these detailed examinations includes a vision measuring system, Baty Quadra-Chek Profile Projector, vernier calipers and a verticality gauge.

Glass fitness for purpose testing

Our extensive and advanced tests determine whether your product is suitable against relevant international, national, industry or in-house standards and specifications. We provide a comprehensive range of mechanical and physical product performance testing and analysis for a range of glass products. They include domestic and trade drinking glasses, bottles, jars, flat glass, furniture, pharmaceuticals and specialist glassware.

Our experts can assess the capacity and headspace, coatings performance, impact resistance, internal pressure resistance, thermal shock resistance and vertical load resistance. The rigorous tests will determine whether your products are fit for purpose and can perform under the strains they are expected to withstand.

Glass property measurement

Our expert team of glass technologists, chemists and analysts can determine a wide range of properties within your glass.

We can perform tests that determine the electrical properties, glass density, liquidus temperature, littleton softening point, refractive index, colour, light transmission and absorbance, temperature-viscosity, thermal and solar properties, dilatometry and thermal expansion, and refractory corrosion and stability.

These services are often used in conjunction with our technical consultancy, research and development, or composition development services. This collaboration can help you optimise production, troubleshoot issues and develop new, novel or exotic glass types.

Environmental and emissions

Our team can work with you on a variety of environmental projects, from recycling schemes, glass re-use and specialist raw material recovery, to lightweighting of glass products, emissions control and environmental impacts. As well as in-house laboratories and on-site mobile laboratory analysis, we have dedicated facilities for glass development and pilot scale glass manufacturing and testing.

Glass production, processing, and packing line audits

Our glass production and processing experts provide manufacturers, suppliers, brand owners and customers with line and process audits to optimise glass production, processing, and food and drink operations. We work with companies involved in all stages of glass supply, from raw materials through to the end product.

In emergencies, we can undertake site visits at short notice to identify issues quickly, allowing production to resume and minimising financial losses.

Client testimonials

Case Studies Relating to Glass Manufacturing

Additional services

R&D and innovation

We have unrivalled glass expertise across a broad range of sectors and can help you develop and optimise your scientific glass applications.

Training and webinars

Our in-house and external training courses teach organisations about various areas of glass production, such as packaging, analysis, and performance.

Consultancy

Our technical experts can provide you with market advantage, knowledge and technical input to processes or products, or develop entirely new and innovative glass formulations, uses or treatments.