EnviroGlass2 follows on from the hugely insightful EnviroGlass project undertaken in partnership with Sheffield Hallam University.

The original project established that waste streams from other sectors could replace raw materials used in glass manufacturing, resulting in significant cost savings and environmental benefits. The BiomAsh project ran in tandem with it, focusing specifically on developing these ash-based raw materials for green and amber container glass.

The EnviroGlass2 project focused on developing a new biomass-ash-based raw material for use in flint container glass, float glass, glass fibre and ceramics.

Who we worked with

Our grant-funded partners on this project were:

- Sheffield Hallam University – home to one of the leading UK centres of excellence in glass research

- Glassworks Services – raw materials supplier to glass industry

- Ashwell Biomass Solutions – providing engineering solutions to the biomass incineration sector

- Power Minerals – distributer of Drax and other ashes, supplying 1.2MT/yr ash

- Templeborough Biomass Power Plant

The work we undertook

The project began with analysing and testing more than 20 biomass power plant samples, then selecting the most promising to move forward with.

We then completed the melting process using a pilot scale pot furnace at VitriTech, whilst conducting environmental emissions tests.

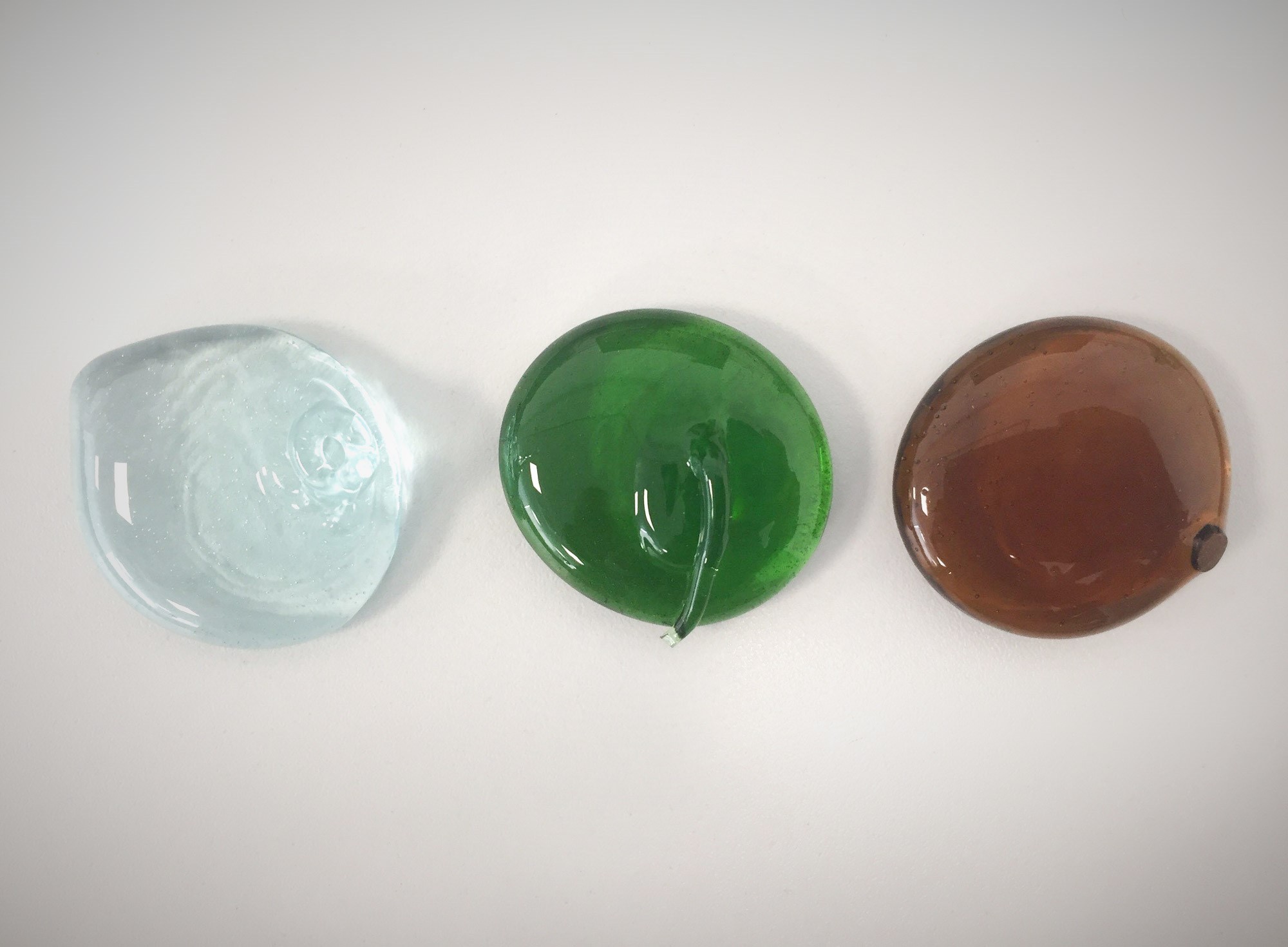

Once the glass samples were created, we undertook characterisation tests, analysing the chemical composition, colour and viscosity.

We also monitored the processing costs of manufacturing glass in this way.

The results of the project

Glass quality

The characterisation of the glass samples showed that the desired chemical and thermal properties could be achieved using additions of ash. This establishes that the ash-derived materials we developed are suitable in the manufacturing of flint, amber and green container glass, without compromising on quality or durability.

We were able to reformulate the glass to achieve a lower-melting-point, and faster melt-rate glass compositions.

Environmental and cost impacts

The emission results demonstrated that there was no negative impact in using ash, as there were no noticeable differences between batches containing ash compared to those without.

Using these new raw materials will, in fact, have significant environmental benefits. It will reduce energy requirements by up to 7%, with associated energy and carbon emission savings, and reduce UK-landfill by up to 75kT/yr.

Currently, the cost of using these new materials is comparable to traditional materials when energy and carbon savings are considered. However, cost savings are expected to increase as energy and carbon process increase and processing systems develop with scale.

“This technology tackles all three aspects of the energy trilemma. It uses recyclable materials which delivers energy and cost savings. It delivers a reduction in CO2 emissions. Plus, it secures future energy and raw material supplies by introducing novel, sustainable waste materials from the renewable energy sector.”

– Marlin Magallanes, principal technologist.

Next steps

We are actively looking for glass manufacturers interested in this technology so we can support them with the qualification process of this type of raw material. We believe introducing these new materials will benefit the glass industry worldwide.

The technology has also been expanded to include the other foundation industries of cement, paper and ceramic in the follow up project, EnviroAsh. Read more about the project.

Work in partnership with us

If you have a project our specialists can help with, contact us to discover how we can work together.