This project brings together partners with expertise in additive manufacturing, glass technology and orthopaedic implants.

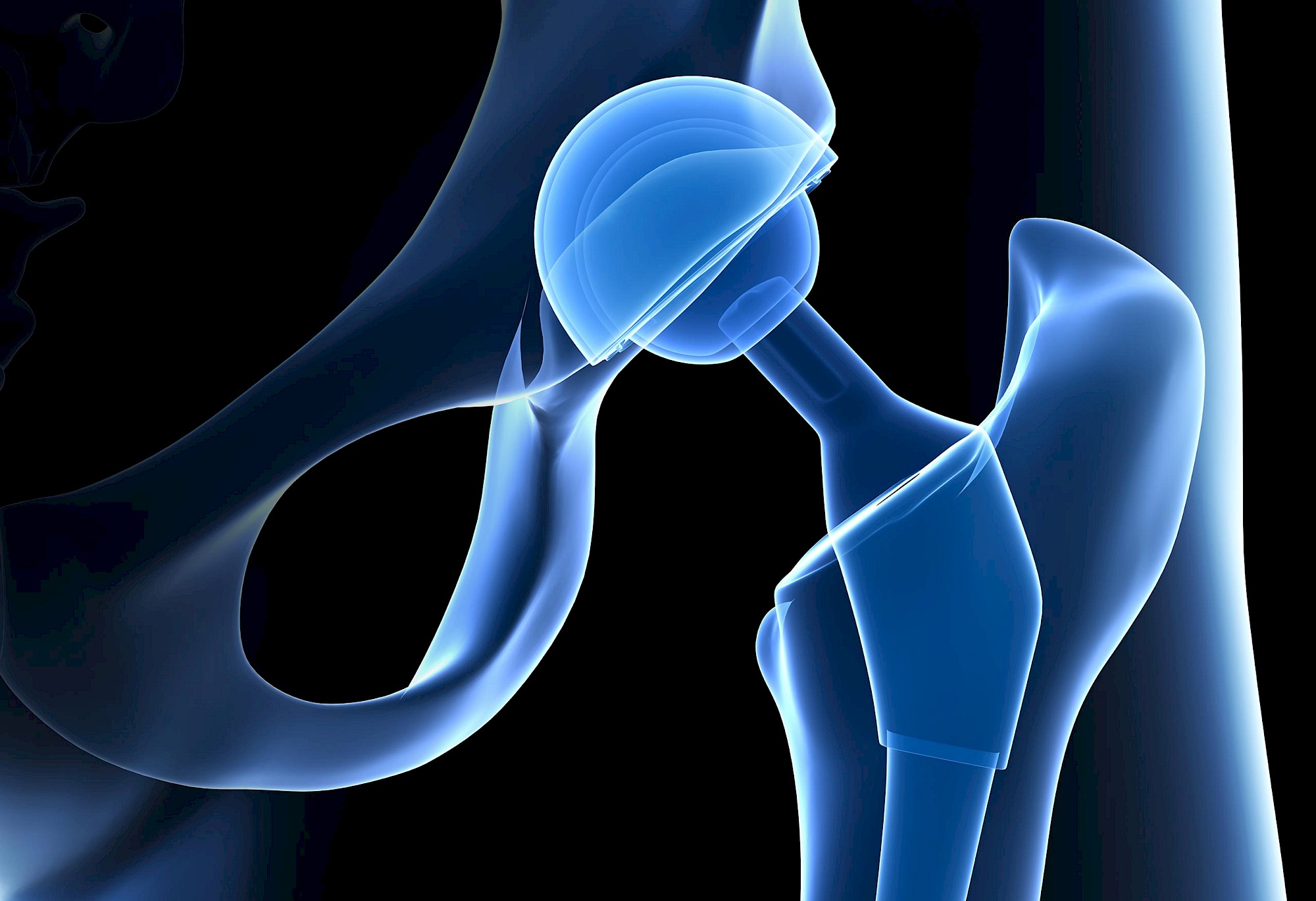

The aim is to develop the next generation of coatings for orthopaedic implants such as hip replacements.

The new combination glass and metal coatings will have better mechanical stability and faster integration with bone thus improving long-term clinical performance and reducing the revision rate. This will deliver a significantly better clinical outcome for patients and savings for the health service. The technology developed during this project has the potential to transform the manufacture of orthopaedic implants and has applications in other fields requiring specialist combinations of glass and metal.

Part of a £8.4 million Government investment programme, ‘ Inspiring new design freedoms in additive manufacturing’, funded by Innovate UK, the national innovation agency and the new name for the Technology Strategy Board, Glass Technology Services is working in partnership with JRI Orthopaedics, 3T RPD, Delta T Devices, The Mercury Centre for Innovative Materials and Manufacturing (based at Sheffield University) and the Manufacturing Technology Centre, to develop 3D printing, specifically an innovative additive manufacturing (AM) process for use in applications within the biomedical and photovoltaic (PV) sectors.

The new AM process will ultimately apply interpenetrating 3D glass and metallic composite structures onto 3D surfaces. The technology will enable the design and manufacture of implants which will have faster integration with bone. This will not only improve long-term clinical performance, but improve the recovery rates for patients and create savings for the health service. The project will then translate this technology for use within a novel light sensor for the PV industry. Glass Technology Services will be responsible for developing novel glass formulations that are compatible with this AM process and will play a key role in developing and building customised additive manufacturing equipment that can build 3D glass-metallic structures.

Project partners

- JRI Orthopaedics Ltd

- Glass Technology Services

- 3T RPD Ltd

- University of Sheffield (Mercury Centre)

- Delta-T Devices Ltd

- Manufacturing Technology Centre Limited.