Thermal stress is caused when part of the glass becomes locally hotter, or colder, than the surrounding glass. This temperature mismatch causes stress from the localised expansion/contraction of the heated/cooled regions when constrained by the rest of the glass. If this stress becomes too great, the glass will crack.

In architecture, the most challenging seasons for thermal fracturing are Spring and Autumn due to the sun sitting low in the sky and the night temperatures dropping. In Summer, although the sun can be warmer and stronger because it’s overhead, this puts less direct heat onto the glass panes and creates less thermal stress. Different types of glass can suffer from thermal stress failures, creating different breakage patterns. Keep reading to find out more.

Thermal failure meaning

First, let us quickly define thermal failure. Put simply, this is glass breakage due to thermal overstressing, such as sudden hot or cold temperatures (aka Thermal Shock). The difference in temperature across the surface or through the thickness of the glass causes the article to break or shatter.

The types of architectural flat glass

Float glass

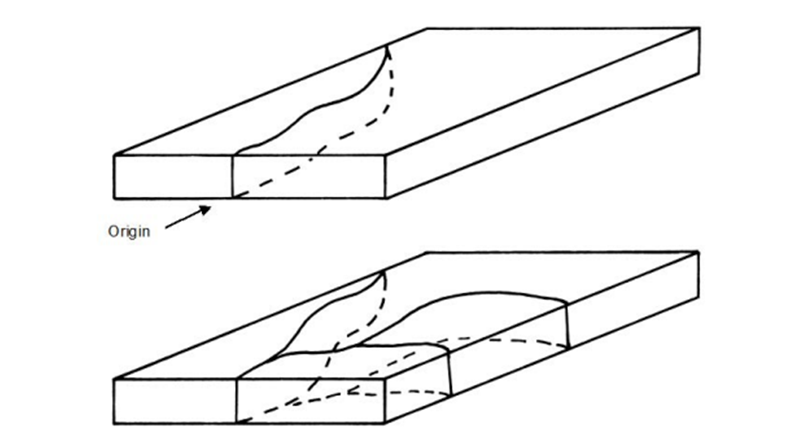

Annealed float glass is not safety glass and is unable to withstand harshest conditions. For this reason, it shows reduced strength and durability compared to the other glasses discussed below. Due to its lack of toughening, annealed float glass is more likely to suffer from thermal failure if part of the glass panel is in the sun while the other is in the shade or air conditioned. For example of thermal fractures in float window glass see Figure 1.

Figure 1: Illustration of a low stress thermal fracture for traditional float window glass.

Heat-strengthened glass

Float glass which has endured additional heat treatments in order to increase the strength but still retains the large angular shards of glass during breakage. Thermal fracture pattern will be similar to that of traditional float glass, slightly more resistant (Figure 1 still applies).

Toughened flat glass

Toughened flat glass qualifies as safety glass due to its increased durability and strength. When glass undergoes the toughening process, it becomes stronger than annealed float glass, even if it is of the same thickness.

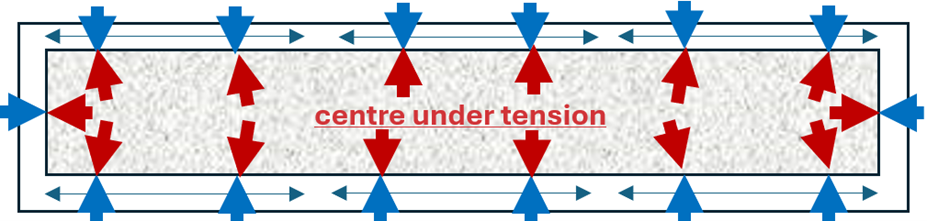

Toughened glass is made from float glass that is cut to size before putting through the toughening process. The process includes putting the glass panels through a chemical or thermal treatment to increase the strength of the glass. This method produces compressive stresses on the exterior surface while placing the interior in tension (see Figure 2), these stresses are in equilibrium. This increases its strength and makes sure that if the glass cracks, it would shatter into tiny, manageable pieces. In the event of failure this protects the people around it (Figure 3).

Figure 2: Illustrations of safety glass, post toughening treatment. Blue arrows illustrate the exterior surface of the glass being in a state of compression. The Red arrows and grey area illustrate the centre being in a constant state of tension.

Figure 3: Broken toughened glass.[3]

Laminated glass

Laminating glass is when two or more layers of glass are bonded together with layers of Polyvinyl Butyral (PVB) bond. Lamination can increase its strength but not to the same extent as toughened glass. Laminated glass may be made of float glass, treated glass, or toughened glass, but its defining feature is that any fractures are held in place by the layered system.

Flat glass breakage

Float, toughened, and laminated glasses are all susceptible to thermal stress and fractures to varying degrees. From our observations, float glass and laminated float glass appear to be among the most common thermally vulnerable flat glasses, followed by heat-strengthened and heat-strengthened laminate glasses, and toughened and toughened laminate glasses. Toughened glass is not typically prone to thermal failure however, it is not an impossible failure. Of course, this all depends on any preexisting flaws or defects and their distribution relative to the application of the thermal stress.

We have some reference materials that we have created internally to document thermal failures in flat, container, and pharmaceutical glass. Join us for our failure analysis training course to see them: Glass failure analysis course.

Other types of glass defects

- Nickel sulphide inclusion. NiS inclusion is a naturally occurring phenomenon that can happen throughout any piece of glass. A breakage due to nickel sulphide inclusion in toughened glass will break in an identifiable butterfly pattern that radiates from a single point - this is where the nickel sulphide changed size due to a phase change and the glass could no longer accommodate it. For more information on NiS inclusion, please take a look at our blog article: “What is nickel sulphide inclusion in glass?”

- Other glass failure analysis – Are you interested in learning more about fracture patterns in a variety of glass types (flat, container, or pharmaceutical glass)? Sign up now for our Failure analysis course “Glass Failure Analysis | Webinar | Glass Technology Services (glass-ts.com)”

References

[1] Quinn, G.D. (2020) NIST Recommended Practice Guide: Fractography of Ceramics and Glasses. https://doi.org/10.6028/nist.sp.960-16e3.

[2] Quinn, G.D. (2020) NIST Recommended Practice Guide: Fractography of Ceramics and Glasses. https://doi.org/10.6028/nist.sp.960-16e3.

[3] This Photo by Unknown Author is licensed under CC BY-NC

How Glass Technology Services can help

Here at Glass Technology Services, we offer a range of services including glass failure analysis where we will diagnose and determine what causes the glass to break. We can also complete preventative quality assessment to help stop the issue from occurring again in the future. With our extensive knowledge and unrivalled expertise, we provide tailored services and guidance to help you work with glass more effectively.

If you think we could help you and your business, please contact us with any questions you may have, or take a look at our case studies to see our past work.

Free webinar: An overview of glass failure

Get access to the webinar