The current focus on delamination could be clouding the bigger pharmaceutical glass packaging picture and narrowing the options for potentially more cost-effective solutions, according to leading analysts at the experts in glass, Glass Technology Services.

Daniel Capon of independent experts Glass Technology Services said that there was a clear trend to badge any perceived problem with glass used in pharmaceutical packaging as delamination, when in fact many resulted from other causes, some of which were potentially much simpler and cheaper to remedy.

“It is vital not to make generalisations, based on recent product recalls,” said Daniel. “Glass containers remain the preferred choice for most medicinal products and risk can be mitigated and controlled to ensure both product quality and patient safety.

“Where I think the industry could be missing a trick is in not assuming delamination in the first instance, but instead analysing each appearance of flakes or particles to address the root cause.”

Based on experience of samples sent to Glass Technology Services for delamination analysis, Daniel said that often what looked like tiny glass fragments, flakes (lamellae) or deposits, were actually naturally occurring compounds that had precipitated out of solution and dissolved back into the solution by the time the sample reached the laboratory, or were foreign bodies introduced during subsequent production and filling processes or by the end user.

Defining delamination

The true source of delamination in the case of borosilicate type 1 glass is flame working of the glass which can cause boron to volatilise from the surface of the glass. This leaves behind a silica-rich surface layer which has a different thermal expansion to the bulk glass, this in turn can cause the surface to flake off when exposed to variances in temperature, for example.

In the case of soda-lime-silica type III glass, the term delamination is used to describe the effect which occurs due to constant attack of the glass surface from the liquids in the container, which leaches the alkaline components of the glass resulting in a more alkaline solution.

This in turn increases the rate of attack until a skin of predominately silica is left on the glass surface, which can eventually detach and be seen as very thin shimmering particles within the solution. This effect can even occur with glasses which have good durability where exposed to high or cyclic temperatures.

“Independent testing can provide essential information to demonstrate due diligence and compliance, in the event of any litigation,” said Daniel. “It could also avoid costly product recalls. At the very least, it can ensure that you are focusing on solving the right problem.”

Propensity Pre-screening

Recent changes to the United States Pharmacopoeia (USP) include a new informative chapter <1660> regarding delamination propensity pre-screening to assess compatibility between drug products and their packaging.

This pre-screening package was made available by Glass Technology Servicesin advance of the USP’s publication last December and an informative article regarding the recent USP and European Pharmacopoeia (Ph. Eur/EP) changes is also available on their website.

Laboratory Support

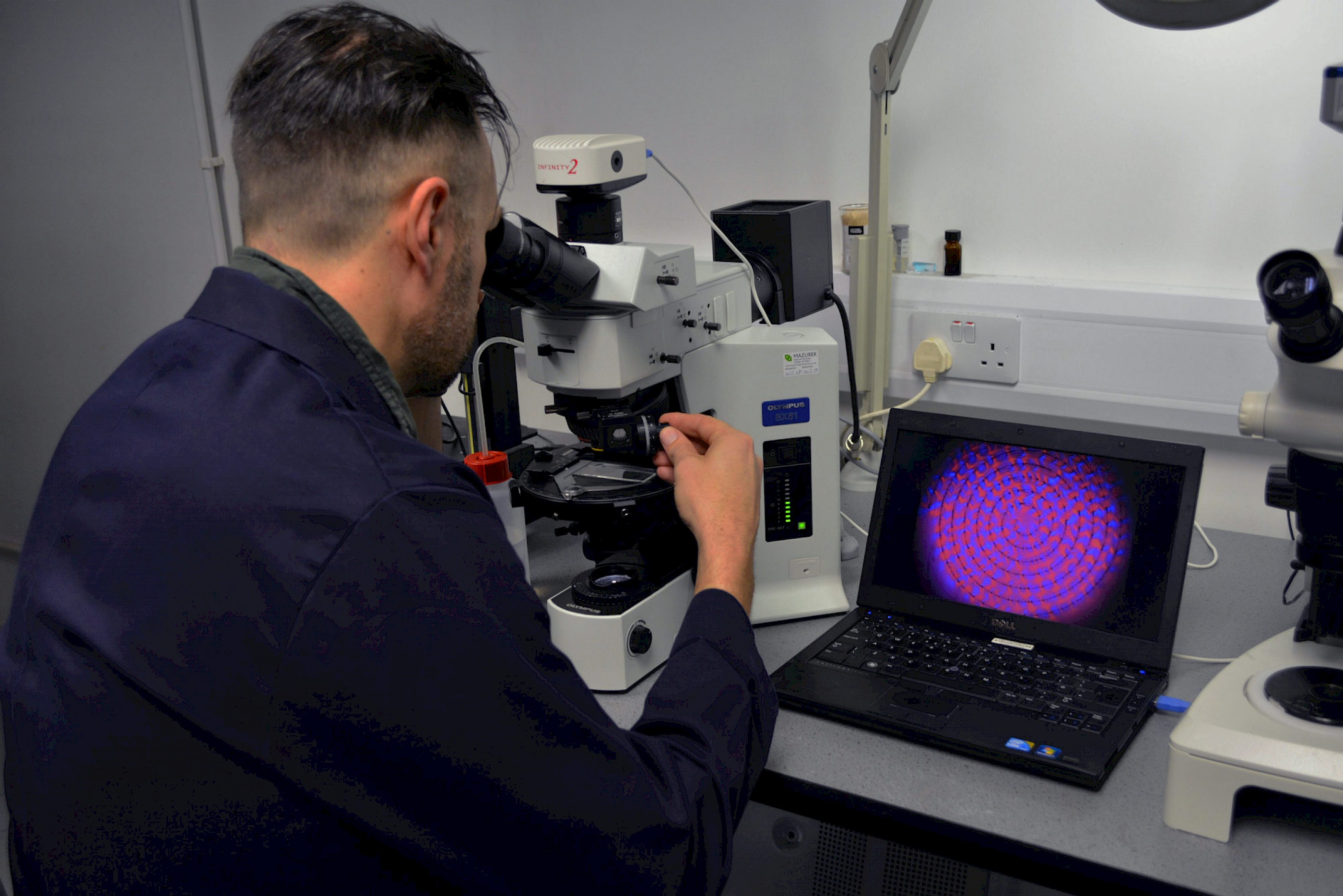

The Glass Technology Services laboratories provide support throughout the biomedical and pharmaceutical sectors including quality assessment, pharmacopoeia, foreign body, composition and failure analyses and the research and development of specialist bioactive glass and ceramics. The laboratory is independently accredited to ISO 9001 and ISO/IEC 17025 andregistered with the US FDA under the GDUFA for API/FDF testing.

The team employs a range of analytical techniques, including SEM-EDS (scanning electron microscopy - energy-dispersive X-ray spectroscopy); WDS-XRF (wavelength dispersive spectroscopy X-ray fluorescence); GRIM (glass refractive index measurement); FTIR (fourier transform infra-red) spectroscopy; ICP-OES (inductively coupled plasma optical emission spectroscopy); UV-Vis spectroscopy and FEA (finite element analysis).

In many cases the analysis from different analytical techniques provides data which enables the experts in glass to determine the root cause of issues and suggest remedial or preventative solutions.