CO-RO is a global fruit drinks provider with brands present in over 80 countries with a strong focus in the Middle East, Asia, Europe and Africa.

Glass makes up a large portion of the brands’ packaging portfolio and they work with manufacturers across the globe to produce packaging close to the consumer. In 2016, CO-RO contacted Glass Technology Services for support with a unique challenge and a longstanding relationship has stood ever since.

We spoke to CO-RO’s Director of Global Packaging, Alison Nyman about the relationship and what it means to the business.

“Lots of things have helped to cement the relationship. When it comes to technical expertise, it is not just Product Performance testing, we have a holistic relationship where we are supported on various levels for example design development and assessment – including theoretical modelling and FEA, mechanical testing, technical audits, quality assessment, failure analysis and technical consultancy projects for the growth of our glass business - Glass Technology Services is an extension to that business and that’s how we regard it.”

Alison joined CO-RO in 2016 to create a global packaging function, within R&D. “I quickly learnt glass was one of the dominant packaging formats at CO-RO and with manufacturers across the globe, it posed a number of challenges when developing new bottles.

“I contacted a former industry colleague and glass manufacturing expert who recommended Glass Technology Services. In collaboration, we have built and continue to refine a process and methodology that enables CO-RO to design, develop and commercialise new bottles that are right first time, on a repeatable and consistent basis.”

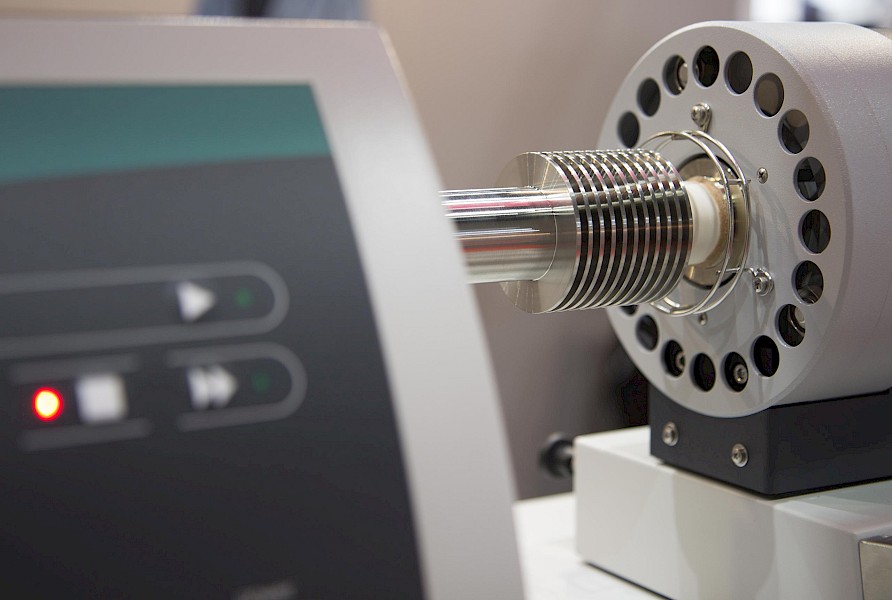

Using TEC7 testing methods

TEC7 testing is a proactive suite of tests that gives brand owners and/or manufacturers confidence in the product and its performance in the market.

“Fundamentally, TEC7 underpins the development process we have at CO-RO,” says Alison.

“It allows us to be very precise - to speak with data and manage with facts, giving glass manufacturers and our bottling plants the information, they need in the language they speak and best understand. Fundamentally, the process is evidence based and supports the exchange of validation and qualification test data, that can then be utilised to agree and set mutually aligned specifications and standards, with confidence and certainty.”

CO-RO’s use of TEC7 testing is a mutually unique application - TEC7 is a set of standards designed for carbonated beverages and yet CO-RO do not pack any carbonated beverages into their glass bottles – “This is where Glass Technology Services expertise came in” explains Alison.

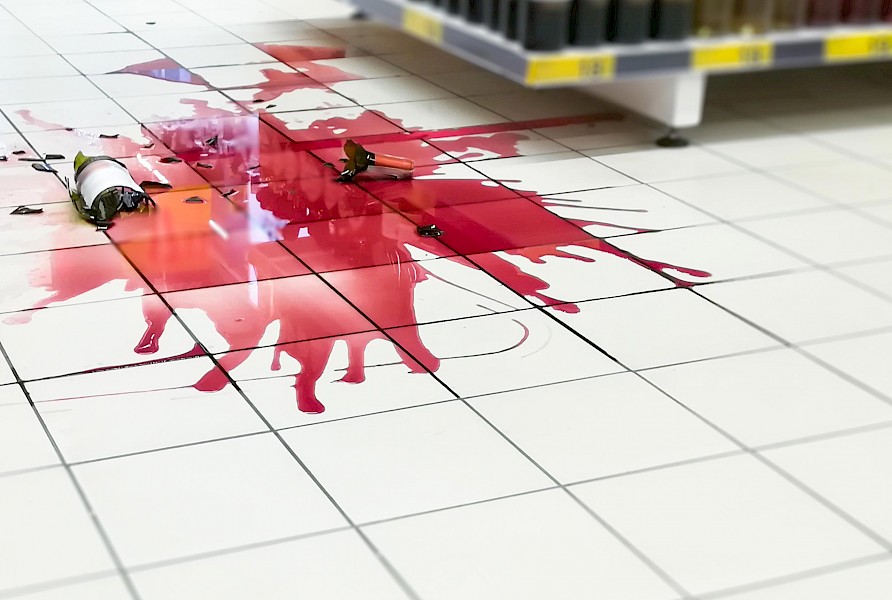

“We pack highly concentrated products into glass bottles in climates around the world where the temperature can reach over 40 degrees on a regular basis. This presents a unique challenge that must be considered within the scope of our early phase development work.

“While we undertake our development work in temperate climates at Glass Technology Services in Sheffield and our development laboratories in Denmark, it is vital that we consider and assure fitness for purpose in such adverse climatic conditions. The unique behaviour of our product necessitates very specific, guaranteed performance standards.

Recognising that, at elevated temperatures, CO-RO’s product behaves similarly to a carbonated beverage, development of the CO-RO bottles, against the TEC7 standards, provides confidence and certainty in their performance capability, as and when they are exposed to very high temperatures.

“TEC7 gives a level of predictability and assurance that is vital to successful execution across our global supply chain” says Alison, “We’ve structured our development and testing protocols so we can understand and challenge the likely behaviour of the bottle and allowing us to successfully manage reproducible, worldwide implementations with agility, flexibility.”

Mutual benefit

Partnership is the keyword here and the relationship with CO-RO is one that works both ways.

Product Performance manager, Graham Morris explains, “We are very pleased to have built a brilliant relationship with Alison and CO-RO, working on a number of areas – proactively including design assessments and specifications, TEC7 testing, quality assurance and consultancy as well as reactive support helping identify production issues.

“As a business, we have gained a lot of knowledge through the partnership about their manufacturing processes and the potential problems they may face, to enable us to identify corrective actions in advance and apply that knowledge – this is due to Alison’s openness to share information before and after the analysis.

“We have also been able to expand our service packages such as solid works and FEA analysis through CO-RO’s willingness to develop the relationship further.”

Alison says, “As long as we are in glass containers, which is part of our legacy and heritage, we will always find ourselves collaborating with Glass Technology Services."